We provide digital ceramic decals at the world lowest price.

Decals using lead-free pigments are food safe.

Only A4-size sheets (210x297 mm, 8.3x11.7 in) are available.

Our digital decal technology is supported by Ineqs and CTG Printtec GmbH.

Price of decal:

One full-color sheet is \1,380 (about $11.5) without requrement of minimum order or initial setup fee.

Frequently asked questions:

1) Why is it so cheap?

Ans.: Because we are not using screen printing. We are using a color lazer printer with special toner system.

2) Does the price change with the number of colors?

Ans.: No, because we are using color laser printer.

3) Can you ask our help to arrange materials on an A4-size sheet using computor soft?

Ans.: Yes, it is a free service. But please do not expect too much.

4) Can you make decals from digital camera photos?

Ans.: Yes, just sed us your photos (jpg) by e-mail. We will arrange them on an A4-sheet as you like.

5) How is the color of decals?

Ans.: Please see below.

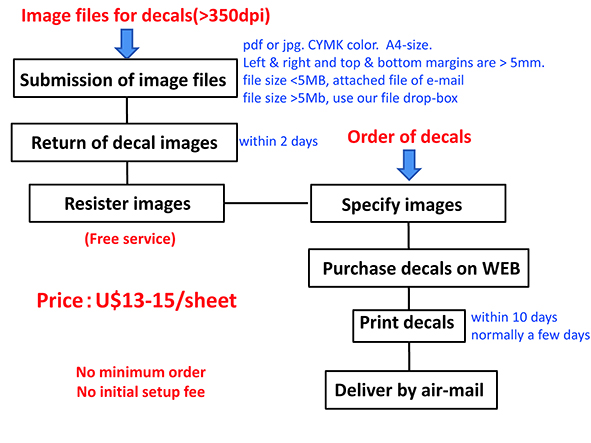

6) How is the flow of order?

Ans.: Before ordering decals, you have to provide A4-size images of pdf or jpg (above 350dpi). If the file size is less than 5MB,

you can send them as attached files of e-mail to shopmaster@ceram-arts.com .

Otherwise, please use our file-drop box.

We will make decal images from your image files. After your checking decal images ,decals will be prepared and delivered by air-mail. Please see below.

6) How long does it take?

Ans.: We will deliver decals within 10 business days (normally a few days). Shipping by air mail will take about one week (depends on destination).

Detailed explanation of decals:

1) Type of decals

We are providing the following 3 kinds of ceramic decals.

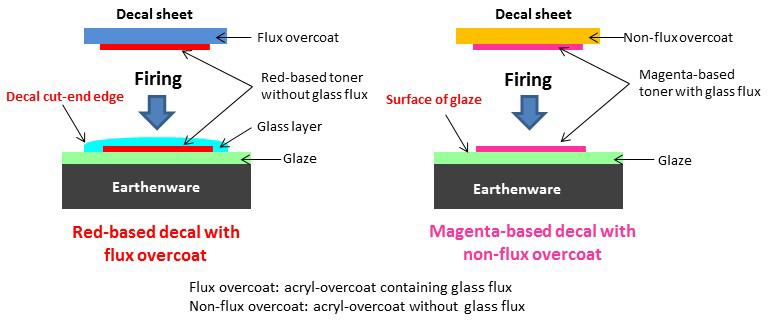

Red-based decal with flux overcoat

Magenta-based decal with non-flux overcoat

Transparent overcoat decal

You have to understand two kinds of decal specification, [magenta-based or red-based] and [flux overcoat or non-flux overcoat].

About [magenta-based or red-based] toners:

Normal lazer printer uses C(cyan), M(magenta), Y(yellow) and K(black) toners to print CMYK images. We cannot use normal toners for ceramic decals

because toners will be fired at high temparatures. Therefore, we have to use special toners made of ceramic pigments.

CYMK toner made of ceramic pigments is available and the maganta-based decals uses this toner system.

However, there is a problem in this toner system. That is the development of pure red prepared by mixing mageta and yellow pigments.

They react at high temparatures to change the pure red to dark red. Because of this problem, magenta-based toner cannot print pure and blight red.

The red-based toner was developed to solve this problem. It employs pure red pigment in place of magenta pigment,

which enable us to use pure red but pure magenta (pink) cannot be obtained. This is the difference between [magenta-based and red-based toners].

About [flux overcoat or non-flux overcort]:

As the ceramics pigments are stable at high temperatures, they cannot be fixed on a porcelain surface without glass flux.

There are two ways to mix glass flux and ceramic pigments. One way is that the glass flux is mixed in an acryl-overcort covering surfaces printed with ceramic pigments.

The other way is that the glass flux is mixed into the pigments themselves. In this case, the addtion of glass flux to the overcoart is not necesssary.

This is the difference between [flux overcoat or non-flux overcort].

The flux overcoat covers the whole surface of decal sheet, which gives us advantage and disadvantage to the red-based decals with flux overcoat.

Advantage: Glossy surface

Disadvantage: Decal cut-end edges will be observable after firing (like thin transparent sellotape)

On the other hand, non-flux overcoat remains nothing after firing. However, there is a limit of amount of glass flux in the pigments, which gives rise to less glossy surface of printed images.

The less amount of pigments in toners caused by the mixing with glass flux restricts the color strength.

To compensate the weak colors, the brightness is sacrificed in the magenta-based decas with non-flux overcoat. The advntage and disadvantage of the magenta-based decas with non-flux overcoat are as follows:

Advantage: No decal cut-end edge

Disadvantage: Relatively less glossy surface and brightless weak colors (not very serious).

Our recomentadion: We like to recommend red-based decals with flux overcoat if you don't mind the decal cut-end edges after firing.

Most beautiful printing will be obtained by cutting red-based decals along the design. For porcelain arts of alumina ceramics, the red-baed dacals should be selected.

Transparent overcoat decals are the red-based decals with flux toner but nothing is printed.

The transparent overcoat decals are used for glazing of alumina ceramic plates and also for the protection of the desolution of metal ions in pigments into acid foods.

2) Flow of decal order

The resolution of image files should be more than 350dpi.

If you have some questions, please feel free to contact shopmaster@ceram-arts.com

|

Contact Us:

shopmaster@ceram-arts.com

Shipping cost: $4.00

to any nations (air mail)

Payment only by